The Problems Customers Faced

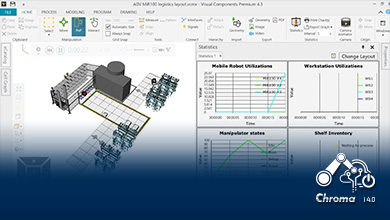

1. The operation of human production line is opaque, and it is impossible to instantly identify bottlenecks.

2. It is difficult to review and formulate improvement strategies in real time. Review processes are often too late in fixing the issue.

3. The acquisition of data by a person is time consuming and biased.

How we helped

1. Transparent Production Information: real time access to comprehensive data over the production line

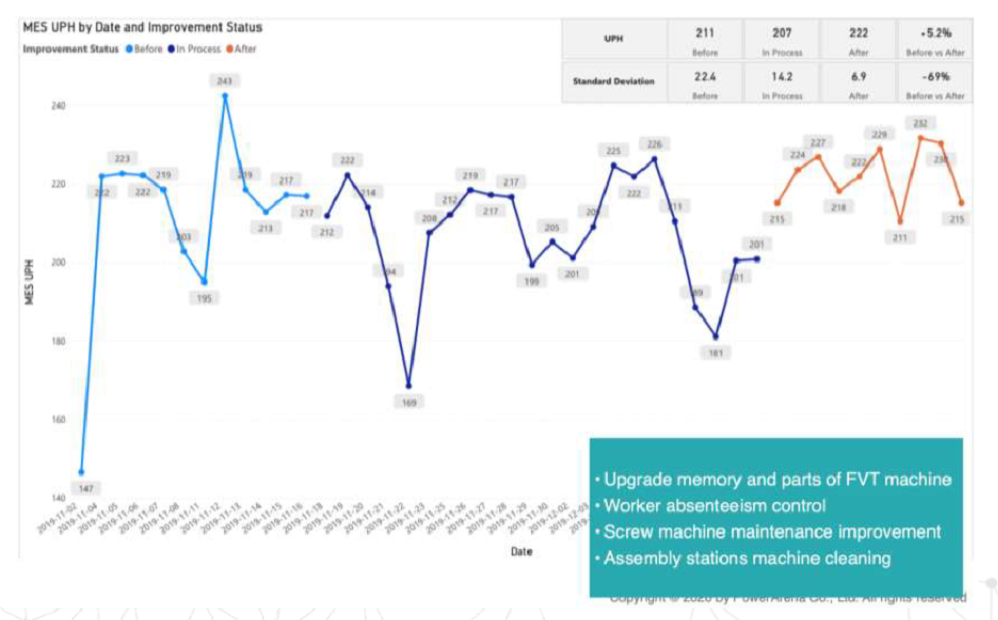

2. Production volume improvement: identifying and eliminating bottlenecks has allowed for increased UPH

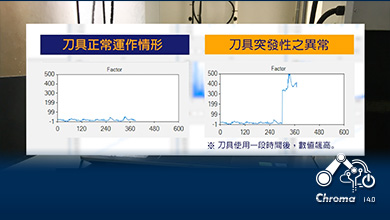

3. Problem Analysis: objective data and a powerful AI algorithm can help find causes for low production output

4. Cost Control: we can provide visualized and accurate models of labor costs and their corresponding value

Customer Benefits

1. Comprehensive data analysis for production yield and quality

2. Clear report on bottlenecks and pain point

3. Optimized scheduling by incorporating OEE data and human performance

4. Reduced solution launch time