Intelligent Manufactuing Equipment Monitoring Solution

MCM-100 with Intel Atom® x7-E3950 Processor-Based Machine Condition Monitoring Edge Platform

- 4CH 24-bit 128kS/s simultaneous sampling analog input

- Each channel includes IEPE 2mA excitation current source that can directly drive accelerometer

- Exquisite design with various I/O interface

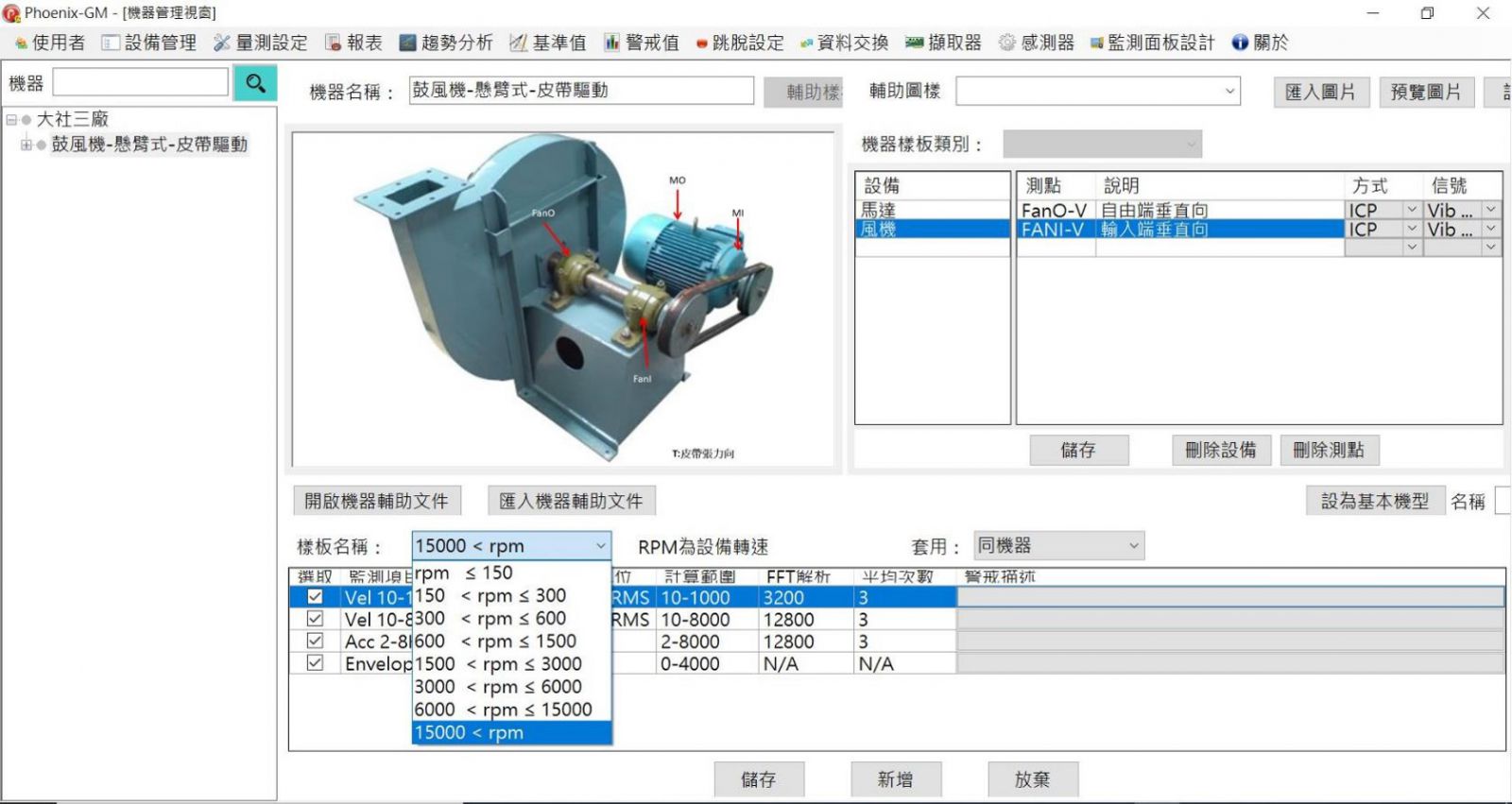

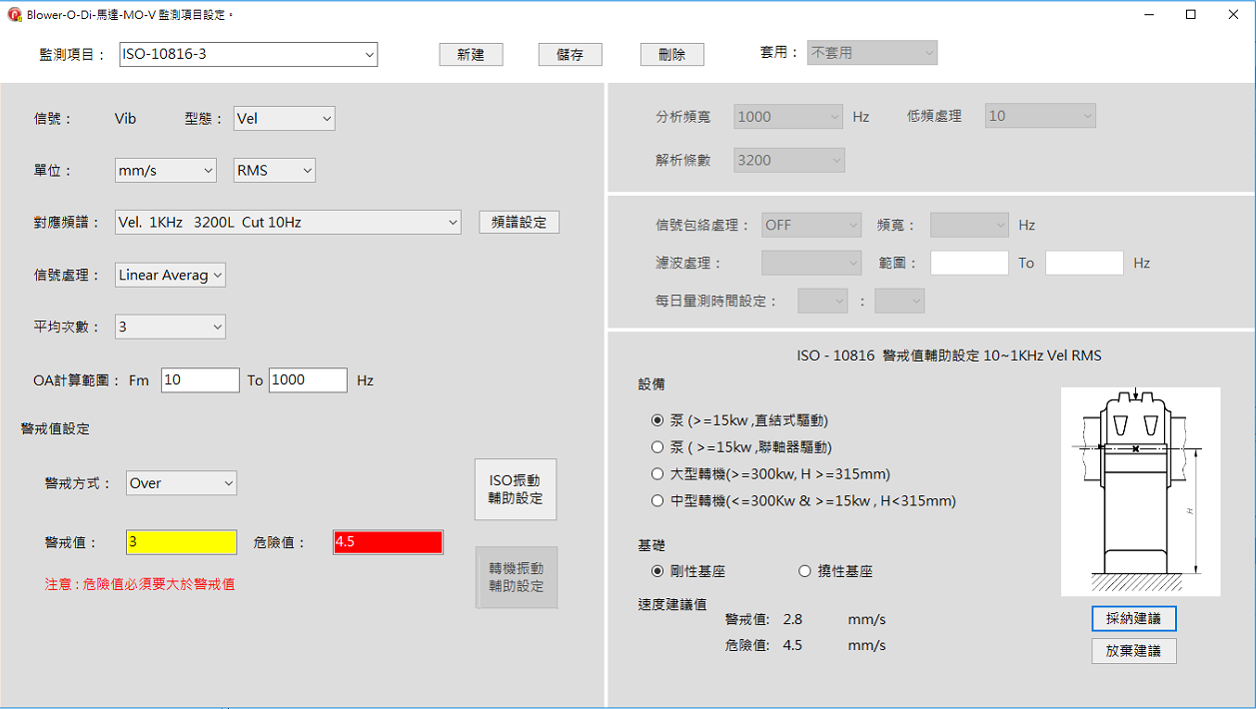

- Optional: Phoenix GM Lite mechanical equipment status monitoring software

- Optional: PCB 603C01 vibration sensor accelerometer

- Optional: Wi-Fi/ 4G LTE wireless module

MCM-204 includes Standalone Ethernet DAQ with 4-ch AI, 24-bit, 128KS/s, 4-ch DI/O performance

- Dual 1Gb Ethernet ports to transmit data back to backend server

- RESTful API reports machine condition

- Supports C/C++ API for streaming data

- Built-in web consule for easy configuration and use as portable DAQ

- Supports custom algorithms to filter data at the edge

- Each analog input channel supports IEPE 4mA current output

- Supports TCP socket(Client Mode)actively transmit data