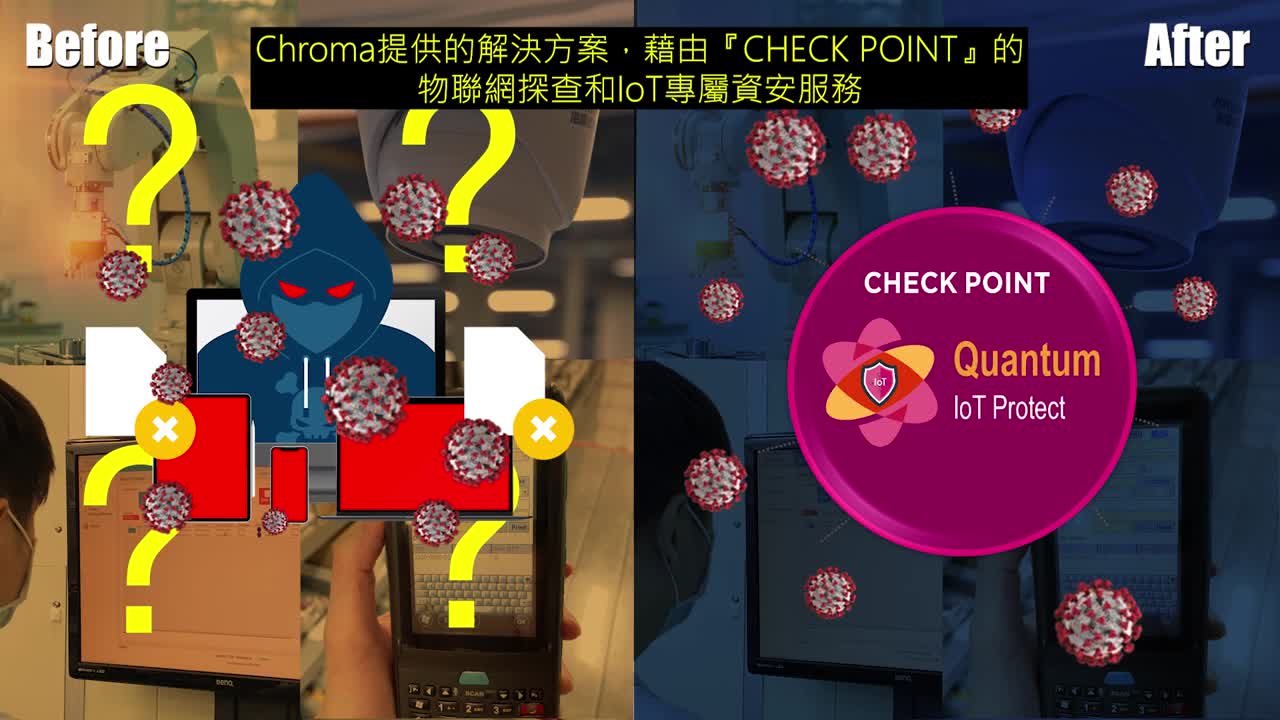

IoT Information Security Management Solution

- Home

- all solutions

-

IoT Information Security Management Solution

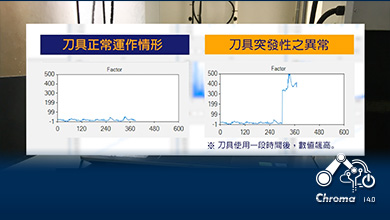

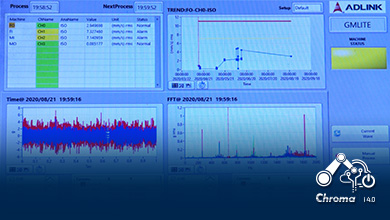

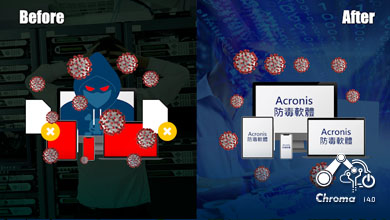

Encompassing network- and device-level IoT security, Check Point IoT Protect prevents IoT cyber attacks, adapting protections to any IoT or OT device across industrial environments. Delivering zero-trust policy tailored per device, IoT Protect uses real time threat intelligence, 60 innovative security services, and on-device runtime protection to deliver a complete, end-to-end preventionfirst strategy for an evolving cyberphysical attack surface.

- Description

- Preview

- Download

IoT Information Security Management Solution Features

- Automated and continuously updated IoT device inventory

- Automatically generate zero-trust access control policies

- Virtual Patch Guard Vulnerability

- Real-name management of all IOT devices to prevent any intrusion on the network

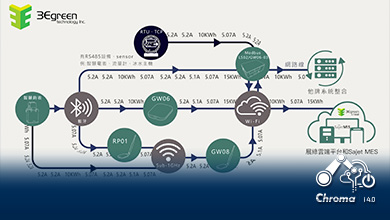

- It has been highly integrated with Sajet MES, which can respond to emergencies in production line equipment

Advantages of Sajet MES Integration

- MES system integrates with Check Point IOT Project to discover status of each IoT devices and avoid production schedule delay

- Unified software security management through MES management platform

- Chroma provides Check Point IOT Protect software operation and Sajet MES after-sales service

- For any abnormal circumstances, Chroma will provide comprehensive one-stop service