Figure 1. Picture of intelligent shelf

Figure 2. Display of materials and parts

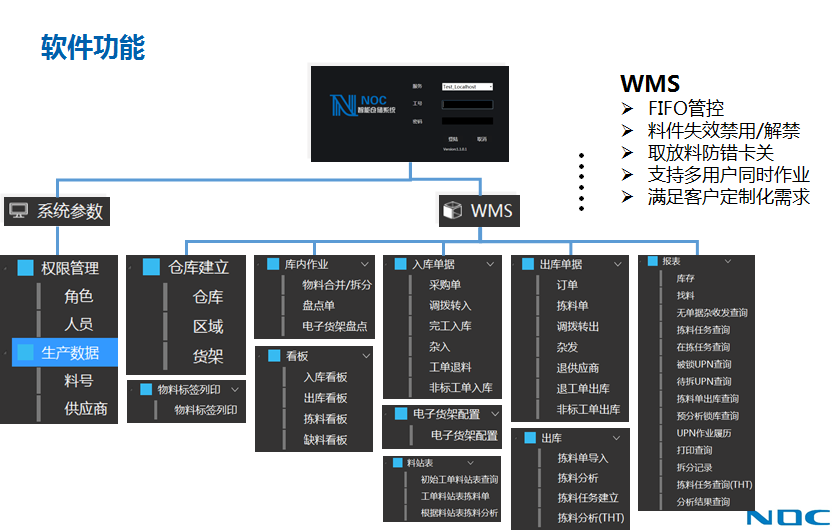

Figure 3. Software Function

Smart Electronic Shelf Solution

- Home

- all solutions

-

Smart Electronic Shelf Solution

The intelligent electronic shelf is a smart tray storage device designed for the SMT industry. It is equipped with intelligent lighting guide equipment on the modular structure shelf to provide accurate, fast and clear indication for the job picking personnel. Improve work efficiency and reduce error rates.

- Description

- Preview

- Download

Smart Electronic Shelf Solution Features

1. Simple management- Reduce manpower, improve efficiency, system control FIFO, personnel skills, no special requirements, can be directly employed

2. Efficiency improvement

- Increase space utilization by 300%, increase storage rate by 50%, and increase refueling speed by 80%

3. Staff skills

- Through the light guide of the intelligent electronic shelf, new recruits can carry out online tally operations according to a simple standard picking program, which effectively speeds up the picking speed.

4. Location reminder

- The alarm light reminds the shelf position, the LED light reminds the storage location, the Led screen shows the remaining quantity and the quantity picked up.

5. Anti-static

- Stainless steel nickel plated, static wire.

6. Beautiful and elegant

- Stainless steel nickel-plated steel mesh, milky white shelf with black light strip.