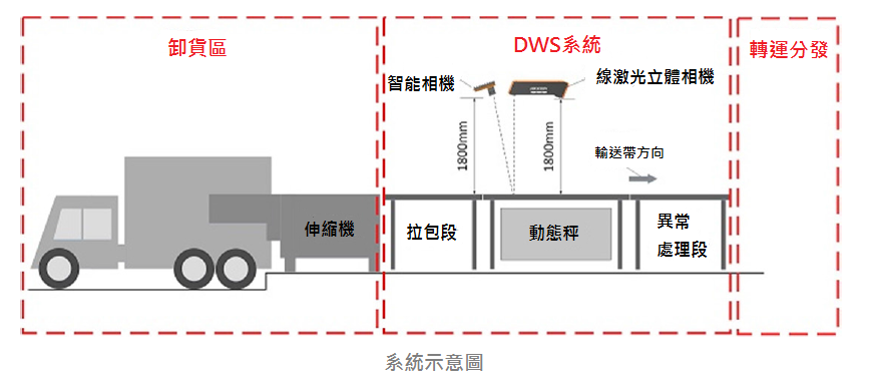

Figure 1. System Structure

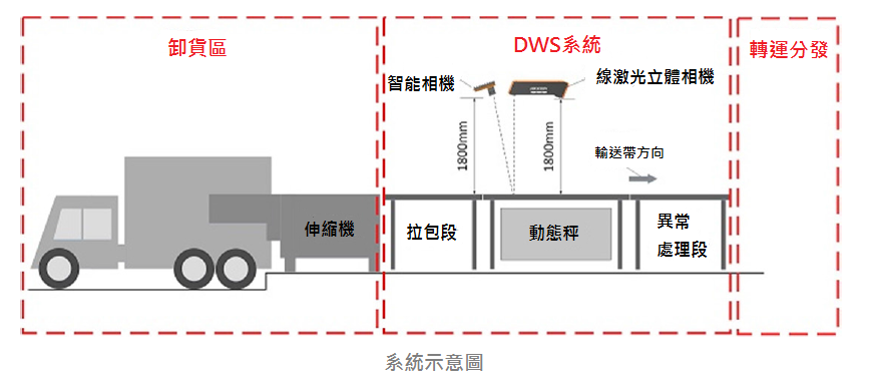

Figure 2. System Structure

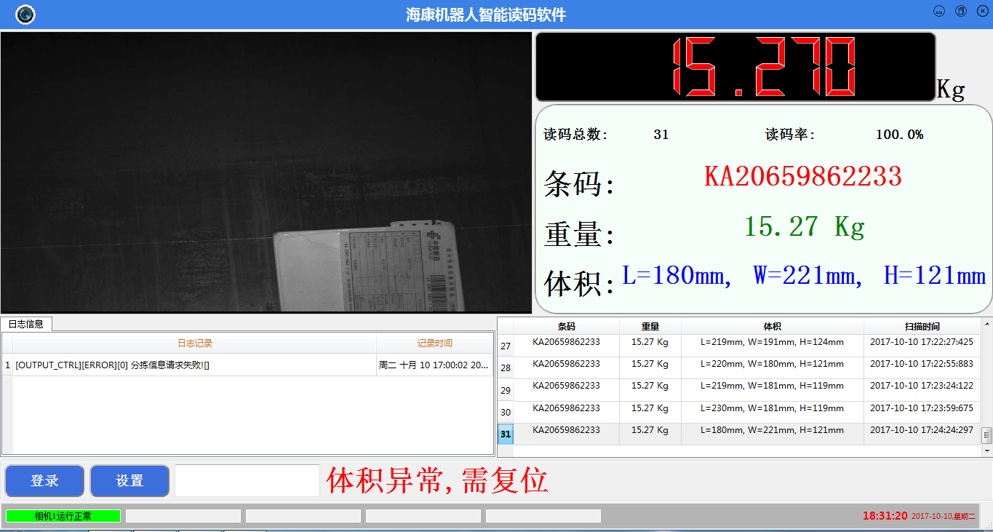

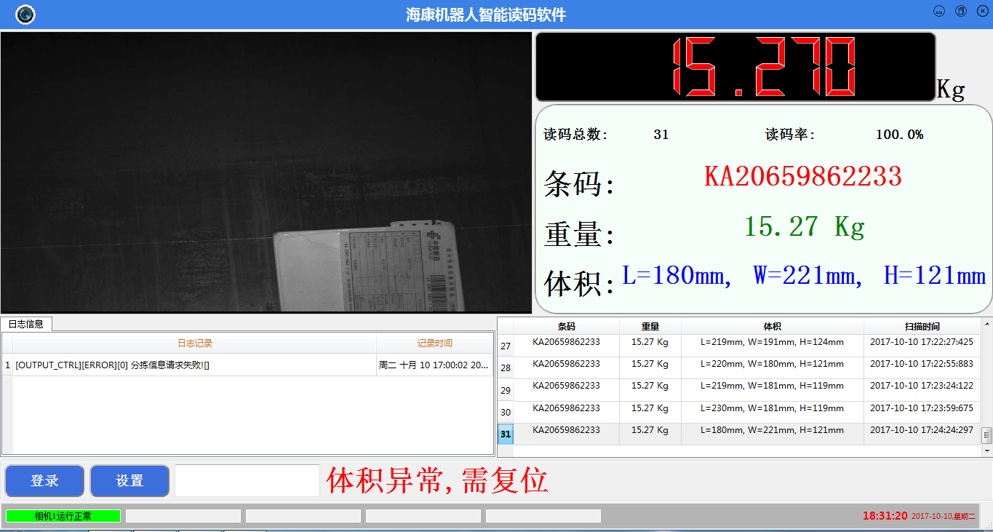

Figure 3. System Interface

Dimension-Weight-Scan System

Dimension-Weight-Scan System Features

1. Automatically collects and uploads the data of package with barcode, dimension, and weight to the serverAdvantages of Sajet MES Integration

1. Monitors real-time material processing progress and inventory quantity and usage