Image recognition and AI data collection can, in real time, compare the difference between actual working hours and standard working hours, identify bottlenecks, and trace pain points. For our customers, we can execute SOP compliance by ensuring completion of all steps, create immediate warning systems for mistakes, and provide quality monitoring.

- Home

-

all solutions

Content Filter

Clear47 results

Safeguarding your assets, ADLINK Equipment Monitoring Solution enables maintenance forecasting and preventative measures before a major failure occurs. Lowering the maintenance cost and improving production efficiency, the solution will ensure an uninterrupted operation.

Provides equipment maintenance plan and calibration management, monitors equipment status and calculates utilization rate through the factory layout diagram incl. calibration,verification and repair management.

Stratus everRun simplifies the process of making applications available—not just some of the time, but all of the time. everRun’s software based solution links two servers together via a virtualization platform that pairs protected virtual machines to create a single operating environment. The entire application environment, including data in memory, is replicated by everRun, ensuring applications continue to run without interruption or data loss. If one physical machine should fail, the application continues to run on the other physical machine without any interruptions or data loss. If a hardware component fails, everRun substitutes the healthy component from the second system until the failed component is repaired or replaced.

Stratus ftServer® is a fully integrated, continuously available hardware and software solution for running tier 1 business critical workloads and manufacturing operations and control applications. Offering better than 5 nines availability, ftServer eliminates unplanned downtime and data loss, and ensures all transactions are processed and applications are available, helping companies maximize revenue, production quality, and productivity.

Supplies electronic SOP for production line operators, connective with the MES system; and displays the current model SOP immediately when the user scans the barcode.

ztC Edge 110i, a secure, highly automated platform that’s specifically designed for the unique requirements of industrial edge computing. One that’s easy to set up, manage and maintain, and reduces your dependence on IT, allowing you to focus on running your plant—not your computers.

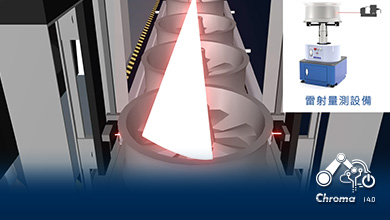

Multidimentional Object Recognition System , MORS, recogizes the model name of the unlabeled workpiece by comparing the feature of it with features of models stored in the cloud server. By MORS , the information of corresponding programes or process line of the workpiece could be obtained automcatically even if no labels on it and no operaters involved. Besides an edge computer to generate feature profile, MORS uses one or multiple laser measuring units equipted on the delicated machine to collect essential data.

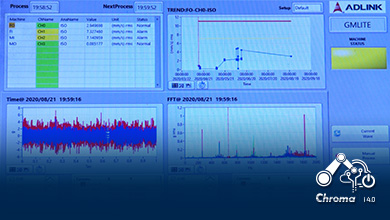

For rotating machines such as motors and reducers, vibration sensors are built, and the Prognosis Monitoring System (PMS, Prognosis Monitoring System) is introduced to perform real-time monitoring and fault diagnosis of the machine, and provide Web pages for monitoring and early warning at any time.

The industrial inspection module that combines machine vision and artificial intelligence can be applied to highly reflective (such as curved metal) and highly trans-missive objects (such as curved glass) to improve the detection accuracy of AOI equipment.